Whereas the upcoming scarcity of metals and uncommon earth supplies could have world implications, amenities in america will doubtless be hit the toughest since home mining and refinement have stagnated in latest a long time. How can they enhance their sourcing methods to realize the targets of Business 4.0 with out pausing implementation or going over funds? Let’s check out sourcing sensible parts.

Good Element Sourcing Points Persist

The worldwide chip scarcity triggered by the COVID-19 pandemic has subsided after roughly three years. Nevertheless, provide chain volatility and provider uncertainty will not be over but. Analysts anticipate a second scarcity will happen, affecting the Web of Issues builders and consumers. Scaling manufacturing can’t resolve the mismatch between provide and demand.

Base, particular, and treasured metals will doubtless be affected. For example, there’s a world nickel scarcity as a result of lack of energetic mines and provide chain volatility. Round 65 p.c of nickel consumed within the Western world is utilized in stainless-steel, so this may have main repercussions.

Uncommon earth parts like germanium, gallium, lithium, and tantalum may even be difficult to acquire. Consequently, sourcing parts like semiconductors, built-in circuits, batteries, shows, and storage media will develop into troublesome for a lot of producers.

Domestically, the shortage of energetic mining operations — the nation’s main nickel mine is ready to shut in 2025 — is a serious contributor to rising provide chain volatility. Various uncooked materials sources are in areas the place regulatory or political elements threaten long-term reliability.

China could prohibit the export of 17 uncommon earth parts in 2024, resulting in extended shortages for Western producers quickly after. Suppliers, builders, and consumers have confronted part shortage earlier than, however the impending scarcity is unprecedented — dozens of uncooked supplies will develop into scarce concurrently.

Why Good Factories Should Deal with Shortage

Digitalization is prime as a result of deploying clever programs is among the many most essential points of attaining the targets of Business 4.0. Good producers should have the ability to reliably supply parts to stay aggressive, scale back operational prices, reduce downtime, and enhance productiveness.

Furthermore, the Web of Issues, synthetic intelligence-embedded sensible sensors, automated energy administration programs, and superior processors are important for bridging the historic hole between operational know-how (OT) and knowledge know-how (IT). The quite a few potential enterprise advantages of integration needs to be motivation sufficient.

Many amenities are halfway via implementation, as navigating IT/OT convergence and legacy system compatibility is advanced. If a second world scarcity had been to happen as early as 2025, they’d lose their aggressive edge. Even those who have absolutely embraced Business 4.0 could wrestle if shortage makes sourcing alternative elements troublesome.

Despite the fact that the CHIPS Act will finally alleviate home provide chain volatility, the federal authorities has solely begun dispersing funds not too long ago — it is going to take years to see the act’s impact. Suppliers will stay unable to show uncooked supplies into working parts till 2027 on the earliest, based on one estimate.

Resilience to Good Element Shortages

Good producers don’t should be on the mercy of risky provide chains and inconsistent provide. There are a number of methods to construct resilience to sensible part shortages.

Provide Chains

Resolution-makers should decide the place their contractors and suppliers get uncooked supplies. Will that supply be affected by mine shortage, China’s export restrictions, or U.S. tariffs? Digitalizing provide chains to grasp shortages permits builders and consumers to boost their sourcing methods and fight volatility.

E-Waste Recycling

Despite the fact that trendy applied sciences include helpful assets, amenities usually discard them improperly. Whereas the world produces over 53 million metric tons of e-waste yearly, it recycles simply 17 p.c. Electrical and digital tools is the fastest-growing waste stream on the planet, with a 3-5 p.c annual development charge.

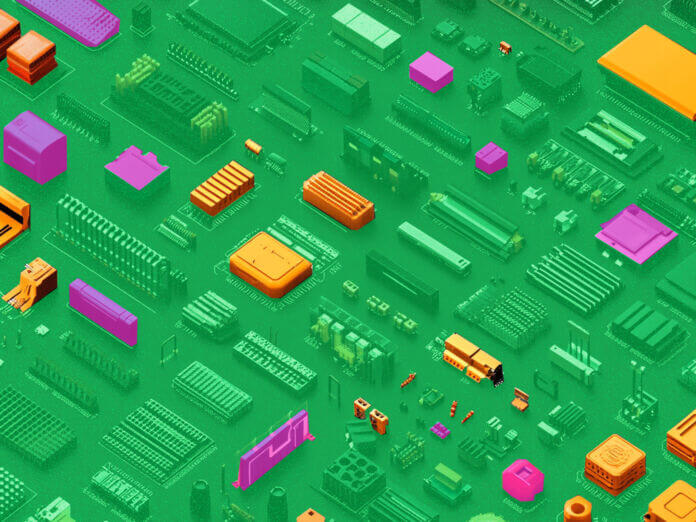

Mining supplies for a printed circuit board is nearly seven instances extra pricey than recycling and reusing them. The large effort that goes into uncooked materials sourcing shouldn’t be wasted by improperly disposing of sensible parts throughout an impending world scarcity. E-waste recycling needs to be a precedence for each producer.

Home Sourcing

The U.S. produces simply 12 p.c of the world’s chips, down from 37 p.c within the Nineteen Nineties. Though the CHIPS Act goals to extend manufacturing drastically, the nation is proscribed by deposit availability. Whereas producers could also be unable to supply sensible parts domestically till 2027, they will use suppliers and contractors that regionally course of and refine imported uncooked supplies.

A Second Scarcity Has International Implications

If dozens of treasured metals and uncommon earth supplies concurrently develop into scarce, typical various sources doubtless gained’t be viable. In spite of everything, each builder, purchaser, and reseller will flock to them to complement their short-term reserves. Factories should act proactively — and rapidly — to stay resilient below these circumstances.