Briefly

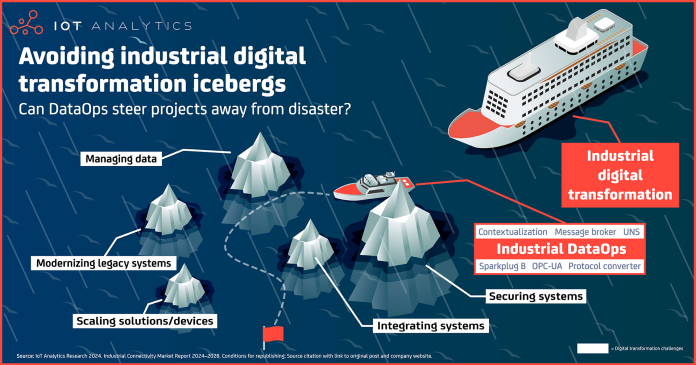

- Industrial digital transformation initiatives, although as grand and promising as they’re, face many obstacles alongside their journeys, similar to knowledge administration and integration complexity.

- Among the many industrial connectivity applied sciences coated in IoT Analytics’ newest market report on the subject, 3 might help steer initiatives away from undertaking icebergs and attain their ultimate locations: 1. Industrial DataOps, 2. Protocol converters, 3. Message brokers.

Why it issues

- Understanding the challenges of digital transformation initiatives and options to assist overcome them might help organizations enhance their possibilities of success.

Industrial digital transformation: An adventurous voyage with unexpected challenges

Digital transformation is like embarking on the Titanic for a daring voyage throughout the North Atlantic—stuffed with potential but in addition accompanied by important dangers. Whereas many corporations set sail on this journey with excessive expectations—believing their digital initiatives to be strong and well-prepared—unexpected connectivity challenges can emerge like icebergs, threatening to show even essentially the most promising initiatives right into a Titanic-like catastrophe.

Very like the iceberg that the Titanic did not navigate round in 1912, these challenges—starting from knowledge silos and incompatible methods to protocol complexity—may cause even essentially the most well-planned digital transformation methods to fall quick and even falter. In 2020, analysis from the Boston Consulting Group discovered that 70% of digital transformation initiatives fail to succeed in their goals. IoT Analytics analysis continues to indicate that main obstacles stay.

Recognizing and addressing these hidden obstacles is essential to making sure that digital transformation initiatives keep on the right track and obtain their supposed outcomes. Luckily, classes discovered from industrial digital transformation case research have helped others navigate the journey, simply as classes discovered from the Titanic have led to fashionable security measures to forestall such tragedies.

Observe: Insights on this article are from the 290-page Industrial Connectivity Market Report 2024–2028 (revealed July 2024), which shares industrial connectivity market knowledge and projections, tendencies, challenges, and the way corporations are addressing their connectivity wants.

Key industrial digital transformation challenges in 2024

Practically two-thirds (62%) of organizations face extreme, unexpected challenges—metaphorical icebergs—throughout their industrial digital transformation journeys, in line with Microsoft’s June 2024 report, Speed up industrial transformation: How producers put together store flooring for a future with AI, which was supported by an IoT Analytics survey carried out for ongoing analysis into good manufacturing facility adoption (N=499).

The next is the share of survey respondents who marked every problem as both extreme or main:

- Cybersecurity at 58%*

- Information administration at 49%*

- Integration complexity at 48%*

- Change administration or cultural resistance at 45%

- Talent gaps at 44%

- Regulatory compliance at 44%

- Legacy system modernization at 43%*

- Reliability and uptime at 40%*

- Scaling options or units at 39%*

- Updating units, property, or methods at 38%*

- Vitality administration and sustainability at 37%

Observe: IoT Analytics plans to publish the Sensible Manufacturing facility Adoption Report 2024 in This autumn 2024 with additional associated knowledge factors. These serious about accessing this report when it’s launched can join IoT Analytics’ IoT Analysis Publication on the high proper of this text to obtain updates on the discharge of those and different studies.

The position of business connectivity

Connectivity on the core of business digital transformation. Connectivity is likely one of the foundational parts of business digital transformation, be it connecting units and gear in factories or within the area. Of the 11 challenges listed above, 7 relate to industrial connectivity (as denoted by asterisks), indicating that connectivity considerably contributes to industrial digital transformation challenges. Connectivity permits corporations to gather operational knowledge for automation and decision-making. The general market measurement for industrial connectivity {hardware} and software program reached $89 billion in 2023, in line with the Industrial Connectivity Market Report 2024–2028 (the biggest portion of the market being industrial automation {hardware} like PLCs or I/O modules).

Navigating hazardous seas: 3 applied sciences that might assist keep away from industrial digital transformation undertaking icebergs

3 applied sciences deal with digital transformation challenges. The report dives into 3 industrial connectivity software program applied sciences that assist handle the problems associated to related OT and IT gear outlined above:

- Industrial DataOps

- Protocol converters

- Message brokers

The next is a deeper look into these 3 applied sciences and the way they deal with digital transformation challenges.

1. Industrial DataOps

“The significance of business connectivity for making the imaginative and prescient of our good factories a actuality is underestimated. A unified shopfloor connectivity structure is the important thing to realizing numerous use instances that we wish to implement.”

Director of Digitalization Manufacturing at Porsche

Industrial DataOps definition (in line with IoT Analytics)

The method of enhancing knowledge high quality by offering construction and context for correct, logical knowledge illustration, guaranteeing usability by downstream functions

Industrial DataOps on the rise. Based on the economic connectivity report, the rising significance of business DataOps is the #1 common industrial connectivity development. Manufacturing landscapes are advanced, with quite a few sensors, machines, and methods interacting. Industrial DataOps helps seize these intricate relationships and derive significant insights by processing, cleansing, and remodeling knowledge into usable codecs, making it simpler for downstream functions to leverage the information for analytics, machine studying, and different functions. By standardizing how industrial property are modeled, industrial DataOps brings uniformity throughout the economic knowledge panorama. This consistency simplifies the mixing and consumption of information by numerous functions, lowering errors.

From a simplified, high-level perspective, industrial DataOps consists of two core parts: knowledge high quality administration and knowledge modeling. The previous ensures dependable OT knowledge for downstream functions by means of profiling, verifying, and cleansing, whereas the latter is the method of making a logical illustration of property, processes, and methods.

Because the established core aspect, knowledge modeling gives a framework that enables totally different methods to speak and combine seamlessly, facilitating knowledge circulation and analytics. A number of knowledge modeling requirements exist in industrial settings, similar to OPC-UA, Sparkplug B, Asset Administration Shell, and Net of Issues.

These requirements assist with two core subelements of information modeling:

- Structuring – This includes organizing entities—i.e., distinct parts representing real-world ideas which have knowledge related to them—into hierarchies—i.e., buildings that manage entities into numerous ranges, establishing relationships and dependencies.

- Contextualizing – This provides attributes, standardizes values by way of particular transformation (and normalization), and particulars relationships each inside the mannequin and throughout interconnected fashions. This course of converts uncooked knowledge into precious data by clarifying what entities symbolize, how they relate to 1 one other, and their roles in a broader community of fashions. Contextualization is achieved by way of attributes, transformation, and relationships.

In the end, all of this results in the creation of a Unified Namespace (UNS). This centralized, real-time framework permits knowledge from all methods, machines, and sensors to be organized and accessed seamlessly. A UNS serves as a single supply of reality throughout the group, making knowledge from numerous sources immediately accessible, structured, and contextualized to be used in analytics, automation, and decision-making. By integrating the rules of business DataOps and leveraging UNS, organizations can obtain higher interoperability, cut back knowledge silos, and make sure that knowledge flows freely and effectively all through the whole digital ecosystem.

Choice of challenges that industrial DataOps might help deal with

- Information administration – Industrial DataOps ensures that knowledge is cleaned, validated, and standardized because it strikes by means of totally different methods, lowering errors and inconsistencies. This makes knowledge dependable for analytics, decision-making, and operational processes.

- Integration complexity – With differing knowledge buildings from totally different related units, normalizing incoming knowledge right into a constant, usable format helps make knowledge simpler for downstream functions to eat and analyze.

Chosen industrial DataOps development from the Industrial Connectivity Market Report 2024–2028

Distributors are creating merchandise that mix IT, ET, and OT knowledge. Operational (OT) knowledge is a hygiene requirement in in the present day’s reworked industrial area. It’s wanted for all industrial use instances. Within the vendor group, there’s a rising realization of the necessity for standard (IT), engineering (ET), and even location and social knowledge to implement the use instances higher to realize the specified outcomes. Industrial software program distributors and OEMs are specializing in offering/integrating connectors to entry these different knowledge sources.

Instance: Norway-based knowledge modeling software program firm Cognite gives Cognite Information Fusion, an information operations platform for manufacturing, asset upkeep, and sustainability use instances in asset-intensive industries. The platform aggregates, cleans, and contextualizes real-time and historic knowledge from OT, IT, and ET sources from a collection of pre-built ‘extractors’.

2. Protocol converters

Cease arguing about [protocols]! Fashionable protocols are a bit of higher than previous ones. There [are] solely actually two sorts of implementations to fret about: Shopper/Server (polled) and Pub/Sub (pushed). We have now to cope with each sorts, and not one of the protocols are going away any time quickly.”

– Jonathan Smart, Chief Know-how Architect, CESMII, in the course of the CESMII On-line Workshop on February 14, 2024

Protocol converter definition (in line with IoT Analytics)

Industrial connectivity software program that performs 2 key industrial connectivity capabilities:

- OT-to-OT protocol conversion

- OT-to-IT protocol conversion

Protocol converters assist methods perceive each other. Typically, methods from numerous distributors leverage numerous protocols—a standardized algorithm and codecs that govern how knowledge is transmitted and exchanged between totally different units, methods, or functions. Software program is required to translate one enter protocol and produce a distinct output protocol. Protocol converters allow this translation between totally different protocols, permitting numerous operational methods (similar to machines, sensors, and controllers) to speak with one another.

Choice of fashionable OT and IT protocols

| OT | IT |

|---|---|

| HART | HTTP |

| PROFIBUS | OPC-UA PubSub |

| PROFINET | MQTT |

| Modbus | AMQP |

| S7 | CoAP |

| EtherNet/IP | DDS |

| OPC UA | |

| IO-Hyperlink |

Choice of challenges that protocol converters might help deal with

- Integration complexity/interfacing with OT networks – Protocol converters allow seamless communication between various networks, lowering the necessity for customized integrations and streamlining the connection of disparate networks.

- Legacy system modernization – Many industrial operations depend on legacy methods that use outdated or proprietary protocols. Protocol converters permit these methods to interface with fashionable platforms and applied sciences by changing knowledge into suitable codecs.

- Scaling options/units – As organizations scale their operations and add new units, protocol converters make sure that new and present methods can talk successfully.

Choose protocol converter development from the Industrial Connectivity Market Report 2024–2028

Protocol converters more and more deployed on the edge. Edge-based industrial protocol converters facilitate instantaneous knowledge switch and activity synchronization in automated methods. Whereas they have been usually put in on desktops and centralized servers prior to now, now they’re being more and more put in on edge units on containers. This expands their functionality and permits functions similar to predictive upkeep, automated high quality inspections, and real-time cloud providers to be put in and carried out effectively on the edge.

Instance: Prosys’ OPC-UA Forge accesses operational knowledge from OPC-UA servers and by way of Modbus, ADS (Beckhoff), and S7 (Siemens) protocols. It could possibly run on a wide range of {hardware} utilizing containers.

3. Message brokers

“At present, MQTT [broker] is utilized by many corporations to attach knowledge from OT machines and processes to IT methods to enhance manufacturing facility course of effectivity, improve OEE, and reduce prices.”

– Ravi Subramanyan, director of business options, HiveMQ

Message dealer definition (in line with IoT Analytics)

An middleman service that enables producers (OT/IT methods) to publish messages to subjects to which a number of customers (OT/IT methods) can subscribe

Message brokers coordinate knowledge messages throughout methods. In industrial setups the place a number of methods should talk, a tightly coupled setup can create rigidity. Message brokers allow a decoupled structure, facilitating scalable communication between totally different methods, functions, or providers, making them best for adoption in digital transformation initiatives. They act as intermediaries that route, rework, and handle messages, permitting methods to speak with out being immediately related or depending on one another. This decoupling enhances the general system structure’s flexibility, scalability, and fault tolerance, making it simpler to deal with excessive volumes of information and combine disparate methods.

MQTT leads the pack in recognition. By far, MQTT—listed above as a well-liked IT protocol—is essentially the most adopted message dealer system in industrial settings. MQTT is a light-weight, publish-subscribe messaging protocol designed for environment friendly, low-bandwidth communication. It could possibly assist totally different message codecs, similar to JSON or XML, and the payloads can carry a spread of knowledge, similar to sensor knowledge, instructions, or settings adjustments. Receiving methods can subscribe to the information subjects most related to them, and the interpretation of the information is as much as the receiving software.

MQTT has 4 key options that make it stand aside from different, lesser-used protocols and make it best for adoption in digital transformation initiatives:

- Connection and matter administration – Oversees community connections, maintains periods, handles matter subscriptions, and ensures message supply

- High quality of service (QoS) administration – Implements totally different QoS ranges, guaranteeing that messages are delivered as per broker-client agreements, from single makes an attempt to assured supply

- Message retention – Allows storing the latest message for a subject to replace new subscribers

- Final will and testomony function – Gives a mechanism for shoppers to designate a message for the dealer if it disconnects out of the blue

One disadvantage of MQTT is that it lacks sure standardizations, which restrict knowledge interoperability throughout industrial functions. To handle this, a further specification, Sparkplug B, is added to the MQTT protocol. Sparkplug B standardizes MQTT message buildings, including time stamps, metrics, sequences, system knowledge messages, and different parts to the message.

Choice of challenges that message brokers—particularly MQTT brokers—might help deal with

- Information administration – Message brokers manage knowledge utilizing subjects, guaranteeing receivers subscribe to and entry solely the related knowledge. Additionally they guarantee knowledge integrity and reliability with options like message retention and simplify knowledge dealing with by standardizing the change of information between totally different methods.

- Scaling options/units – Message brokers are designed to deal with hundreds of concurrent connections and excessive throughput, enabling methods to scale with out efficiency degradation. Additional, by decoupling publishers and subscribers, message brokers permit new units and methods to be added with out disrupting present infrastructure.

Choose message dealer insights from the Industrial Connectivity Market Report 2024–2028

Sparkplug B continues to draw curiosity from distributors. The MQTT wave is making the Sparkplug B specification fashionable. Managed by the Eclipse Basis and primarily based on the MQTT 3.1.1 customary, Sparkplug B is an open specification for MQTT nodes to speak inside the MQTT infrastructure. MQTT is the change protocol, and Sparkplug defines the information despatched. The MQTT + Sparkplug B mixture is an alternate choice to the OPC-UA customary within the opinion of a number of industrial software program distributors.

For instance, a sturdy set of distributors growing SCADA, MQTT brokers, and different functions (like historians, protocol converters, and DataOps options) have carried out Sparkplug B of their merchandise. These corporations embrace ABB, Schneider Electrical, Wago, Inductive Automation, HiveMQ, and Canary Labs.

Analyst opinion: The position of business connectivity for digital transformation

DataOps maintain promise. Very like the fateful voyage of the Titanic, industrial digital transformation initiatives begin with massive celebrations and excessive expectations however face obstacles for a profitable journey—the hidden icebergs. Applied sciences and instruments which have lately emerged—similar to DataOps and message brokers—promise to handle these challenges.

The market could be very nascent. Many of those instruments are nascent, as lots of the market gamers which might be working to raise the instruments (e.g., Cognite, Litmus, Highbyte, or Cybus, amongst others) have been based within the final 10 years. For perspective, the DataOps market section made up lower than 0.1% of the whole $89 billion industrial connectivity market in 2023 and fewer than 0.025% of the entire $269 billion enterprise IoT market. Bigger industrial automation {hardware} and software program distributors solely lately began integrating DataOps options into their general tech stack. One notable instance is AspenTech DataWorks, which is marketed as an “industrial knowledge administration resolution.” DataWorks closely depends on expertise developed by Inmation, a Germany-based firm based in 2013, which Aspentech acquired in 2022.

Progress prospects are robust. Nonetheless, corporations are more and more seeking to undertake these instruments to bypass the undertaking icebergs, and the flexibility of those instruments to assist steer digital transformation initiatives away from connectivity obstacles is a significant component within the excessive projected CAGRs of every by means of 2028:

- DataOps – 49%

- Protocol converters – 12%

- Message brokers – 28%

In flip, IoT Analytics expects the collective industrial connectivity software program section to be a key driver behind general industrial connectivity market development—5% CAGR till 2028.

Sure, DataOps might help steer away from catastrophe however rather more is required. These instruments don’t clear up all industrial digital transformation challenges, as change administration and ability gaps nonetheless stay. Nevertheless, very like the Worldwide Ice Patrol helps ships navigate the iceberg-laden waters of the North Atlantic in the present day, these instruments promise to assist producers navigate harmful factors alongside their industrial digital transformation journey if correctly adopted and used.

Disclosure

Corporations talked about on this article—together with their merchandise—are used as examples to showcase a vibrant IoT startup panorama. No firm paid or acquired preferential remedy on this article, and it’s on the discretion of the analyst to pick out which examples are used. IoT Analytics makes efforts to range the businesses and merchandise talked about to assist shine consideration to the quite a few IoT and associated expertise market gamers. It’s price noting that IoT Analytics might have industrial relationships with some corporations talked about in its articles, as some corporations license IoT Analytics market analysis. Nevertheless, for confidentiality, IoT Analytics can not disclose particular person relationships. Please contact compliance(at)iot-analytics.com for any questions or issues on this entrance.

Extra data and additional studying

Are you interested by studying extra concerning the industrial connectivity market?

Obtain a pattern of the complete market report

The pattern of the report accommodates a holistic overview of the accessible evaluation (define, key slides), gives extra context on the subject, and describes the evaluation methodology.

Already a subscriber? See your studies right here →

The Industrial Connectivity Market Report 2024–2028 is a 290-page report detailing the economic connectivity market, together with market measurement & outlook, {hardware}, software program, protocols, case research, tendencies, challenges, and extra.

This report gives solutions to the next questions (amongst others):

- What’s industrial connectivity (i.e., an industrial connectivity definition)?

- What’s the measurement of the general industrial connectivity market by part, area, and business?

- What are some key tendencies and challenges within the industrial connectivity area?

- What sorts of {hardware} are used for knowledge acquisition, who’re the main suppliers, and the way would possibly the panorama change sooner or later?

- What sorts of protocol converters software program are used for knowledge acquisition, who’re the main suppliers, and the way will the panorama change sooner or later?

- What’s the position of message dealer software program in industrial connectivity, who’re the main distributors, and the way will the market change sooner or later?

- What are the weather of the rapidly evolving area of industrial knowledge operations (DataOps) software program, who’re the main suppliers, and what adjustments are anticipated sooner or later?

- What applied sciences are concerned in transmitting the information from supply to vacation spot?

- What are the most typical architectures for attaining industrial connectivity, and the way would possibly this variation sooner or later?

- What are the most typical protocols used between every layer of the connectivity stack, and the way may this variation sooner or later?

- What are some examples of factories and authentic gear producers (OEMs) utilizing industrial connectivity to create worth (i.e., industrial connectivity case research)?

Associated publications

Chances are you’ll have an interest within the following publications:

Associated market knowledge

Chances are you’ll have an interest within the following IoT market knowledge merchandise:

Associated articles

You may additionally have an interest within the following latest articles:

Are you interested by continued IoT protection and updates?

Subscribe to our publication and comply with us on LinkedIn and Twitter to remain up-to-date on the newest tendencies shaping the IoT markets. For full enterprise IoT protection with entry to all of IoT Analytics’ paid content material & studies, together with dedicate