Life science analysis goes high-throughput, and there’s no turning again.

Sequencing, cell tradition, hybridization assays, and cell screening — to call a number of — are all transferring towards producing extra knowledge in much less time, which requires automation.

For smaller labs, the idea of automating routine duties on the analysis bench is a sexy chance. Nonetheless, it could appear out of attain attributable to quite a lot of elements, together with price, house, and coaching necessities. Thankfully, automation applied sciences have superior a terrific deal within the final decade, making high-value, entry-level automated liquid dealing with platforms and different methods considerably smaller, inexpensive, and simpler to make use of.

Automation platforms can simplify routine laboratory duties in any analysis program, and the advantages don’t finish there.

Enhance Effectivity

For many labs, personnel prices are the very best line-item expense in a analysis price range. Maximizing the effectivity of laboratory employees is paramount to the success and productiveness of a business lab or analysis program.

It is very important be aware {that a} lab doesn’t must be totally automated to learn from lab automation. The obvious targets for automation are repetitive, laborious duties, similar to pipetting and liquid dealing with, that might be delegated to an automatic system. Critically, this recouped time can be utilized for higher-level knowledge evaluation and different laboratory duties. Growing productiveness is simply one of many some ways automated liquid handlers and different automated methods present a return on funding (ROI, Determine 1).

Much less apparent targets for automation and informatics, nonetheless, are the period of time required for experiment planning and routine knowledge evaluation. Software program can be out there to help employees with the right design of routine experiments within the lab and is included with automated liquid dealing with and different automation platforms.

An necessary consideration for labs all for automation is the elevated quantity of knowledge generated by extra automated, excessive throughput liquid dealing with methods. Elevated knowledge era could end in laboratory employees being buried in knowledge or take a look at outcomes with out the evaluation instruments to deal with the elevated workload. Quite than growing the variety of employees devoted to knowledge evaluation, labs can incorporate higher-throughput informatics options to remove knowledge bottlenecks within the lab and enhance the productiveness of the lab as an entire.

Improve Reproducibility

For a lot of small labs, significantly in academia, extra repetitive and laborious duties have been delegated to undergraduates or different college students with little to no coaching or expertise in life sciences analysis for little or no compensation.

Determine 1.A flowchart illustrating the return on funding (ROI) of automation and informatics platforms within the analysis lab.

Whereas this technique could appear cost-effective at first, knowledge generated by much less skilled and less expensive employees could carry a better price ticket in the long term. Points with knowledge reproducibility, accuracy, and failed experiments waste each money and time, reducing the productiveness of the lab. Labs can lose months’ value of labor, for instance, if a mouse colony is badly genotyped and utilized in extremely technical experiments down the highway.

The COVID-19 pandemic highlighted the need of next-generation sequencing (NGS) for diagnostic testing and epidemiological research, and staffing shortages strengthened the function automation can play in productiveness bottlenecks. Labs tasked with around-the-clock processing, testing, and evaluation of specimens can significantly profit from automation by facilitating:

- Pattern processing, testing, and evaluation with fewer employees members

- Staffing labs with personnel with much less specialised coaching

- Improved pattern high quality

- Much less pattern retesting

Importantly, these advantages can prolong to smaller labs that would profit merely from after-hours testing or improved, extra constant pattern prep and knowledge reproducibility. Automation permits these labs to extend productiveness with out the burden of hiring employees for extra repetitive and labor-intensive points of lab analysis.

Lower Waste

Life science analysis reagents are more and more costly. Automated pattern prep and liquid dealing with may help a analysis program’s backside line by decreasing the quantity of waste attributable to minor laboratory reagent spills.

Improved knowledge high quality, accuracy, and reproducibility additionally lower the variety of replicates required to statistically energy a analysis research, bettering experiment effectivity. This decreases the variety of suggestions required for pipetting, the quantity of reagents wanted for a research, and the period of time required to finish an experiment.

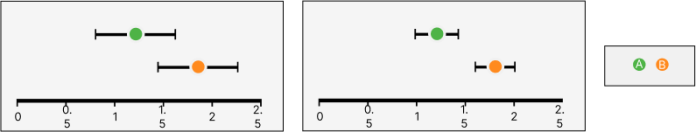

Determine 2 illustrates how decreasing knowledge error can enhance the ability of experimental research. Within the left panel, the variations in particular person knowledge measurements are so giant that knowledge factors overlap between the management and experimental teams. In distinction, the info factors in the proper panel have decrease variability, and there’s no overlap in knowledge measurements between the management and experimental teams.

The shortage of overlap between measurements within the two teams decreases the probability that the variations noticed between the 2 teams occurred solely by likelihood. In different phrases, reducing measurement error – by means of automation or different means — will increase the statistical significance of an experimental end result.

Enhancing the statistical energy of experiments additionally improves the probability of a research detecting smaller results of an experiment variable, whereas lower-powered research will solely catch bigger, extra apparent results (Determine 3). In the end, incorporating automation into laboratory workflows and reducing measurement variability may help research detect experimental results that may in any other case stay undiscovered.

Determine 3. A diagram utilizing a visible analogy to explain how experiments with larger statistical energy can detect smaller experimental results in comparison with experiments with decrease statistical energy. (https://cxl.com/weblog/statistical-power/)

Lower Repetitive Pressure Harm

Let’s face it: individuals have elbows and wrists that put on out and might’t get replaced. Robots have mechanical joints and elements that put on out that may simply get replaced.

Repetitive pressure harm is an actual challenge in laboratories that rely on repetitive, laborious motions as a part of their regular workflow. These accidents additionally are likely to happen in employees who carry out these motions probably the most typically over the longest time frame — probably the most skilled and oftentimes most educated personnel of the lab.

The Nationwide Institute for Occupational Security and Well being (NIOSH) estimates that occupational musculoskeletal problems, together with repetitive pressure accidents, price the U.S. between $13 and $20 billion yearly. The median time away from work for a repetitive pressure harm is estimated at 18 days. A complete of 55% of repetitive pressure accidents within the research have an effect on the wrist.

OSHA’s occupational accidents and diseases price estimator estimates {that a} single case of carpal tunnel syndrome within the office prices an employer $30,930 in direct prices and $34,023 in oblique prices, totaling $64,953. For a business lab with a 3% revenue margin, the corporate should enhance gross sales by an extra $2,165,100 to cowl the whole price of the only repetitive pressure harm.

The losses incurred by labs attributable to repetitive pressure accidents are actual and vital, and disproportionately have an effect on employees with probably the most expertise on the job. Thankfully, automation can remove the chance of repetitive movement accidents within the lab whereas growing employee productiveness and reducing experimental waste and measurement variability.

Keep Aggressive

Maybe most significantly, life sciences analysis and business labs have gotten more and more high-throughput, requiring automation of frequent, repetitive duties and knowledge evaluation to keep up the productiveness and price effectivity of different labs.

The Nationwide Institutes of Well being and different granting companies have taken discover.

Sanger sequencing has been relegated to functions requiring solely probably the most correct DNA sequencing, similar to diagnosing gene mutations in a single gene

Subsequent-generation sequencing is at present magnitudes of order cheaper and quicker than conventional Sanger sequencing

Linkage evaluation research, beforehand used to pinpoint causative gene mutations, have largely fallen to the wayside in favor of exon or whole-genome sequencing

Mass spectrometry has all however changed the Western blot to determine differential expression of proteins

Granting companies pay shut consideration to which laboratories embrace new applied sciences to enhance the effectivity of diagnostics, experiments, and total lab productiveness, and that is typically mirrored in grant and different funding suggestions. This contains using automated liquid dealing with methods that may be programmed to carry out any activity a technician would do with a hand-held pipettor and totally different sized pipette suggestions (Determine 4). This automation frees up personnel time for different lab priorities and knowledge evaluation whereas delegating pipetting to a quick, dependable, and exact automated dispenser.

Determine 4. Frequent laboratory duties that may be automated to enhance lab effectivity and productiveness.

Challenges of Automation

Price of Excessive Throughput Liquid Dealing with

Many labs incorrectly assume that the upfront price of automated applied sciences is just too excessive to justify their buy. Nonetheless, advances in expertise and competitors between distributors have considerably decreased the price of many automated liquid dealing with methods and the funding required to enhance throughput within the laboratory.

Smaller semi-automated liquid dealing with methods, as an illustration, can price as little as $5,000, whereas extra advanced, fully-automated excessive throughput liquid dealing with methods can price as a lot as $500,000. Importantly, there’s an automatic system out there for practically each pipetting activity.

Infrastructure for Liquid Dealing with

Advances in expertise have additionally decreased the quantity of in-house infrastructure required for lab automation. Nearly all methods embrace a pc to program workflows. Many high-level computing assets have been shifted to cloud-based applied sciences that scale back the dependence on on-site server house or in-house computing energy. Nearly all of liquid handlers moreover present their very own refrigeration.

Footprint

Whereas automation could lower the personnel necessities for sure repetitive laboratory duties, it could take up priceless analysis house in already crowded quarters. Over time, the footprint of automated liquid dealing with methods has decreased considerably. In truth, the footprint of most methods is dictated by the scale and variety of plates to run in a given workflow. Liquid dealing with system distributors provide quite a lot of options for labs requiring extra normal excessive throughput liquid dealing with options versus methods that require 24/7 operation with minimal human intervention.

Provides

Many automated methods are designed for compatibility with quite a lot of totally different consumable manufacturers reasonably than only a single, in-house model. With elevated competitors within the lab automation market, distributors are conscious that seemingly innocent modifications, similar to altering the model of pipette tip, can alter the outcomes of extremely delicate experiments. Elevated competitors additionally ensures that the labs are ready to decide on the provides they like primarily based on each high quality and value.

Warmth and Noise

Laboratory tools is infamous for warmth and noise. Fortunately, advances in expertise have improved cooling effectivity in automated liquid dealing with methods, reducing their noise and warmth output. The exact tip becoming of automated handlers might also lower noise within the lab in comparison with the loud, forceful becoming of suggestions onto guide multichannel pipettors.

Key Takeaways

The necessities and workflows for each lab are totally different, making alternatives for automation fluctuate from lab to lab. With a view to decide how automation will influence your lab’s effectivity and productiveness, it is very important think about the next questions (Determine 5):

- Which lab workflows can profit from automation?

- How do laboratory employees really feel automation would have an effect on their workday and productiveness?

- Does our lab wish to automate a number of workflows or begin with only one? Which workflows ought to we prioritize?

- Which automation options can be found for our workflow? What options match our price range?

- Produce other labs used the identical methods? What are the professionals and cons of every system?

Asking these questions up entrance will assist managers perceive the wants of laboratory employees and the priorities of this system, division, or firm as an entire. Moreover, researching the totally different methods out there for prime throughput liquid dealing with and different automation can construct confidence in bigger line-item purchases.

Critically, life sciences analysis is transferring towards larger and better throughput strategies and applied sciences, requiring labs to adapt or undergo decrease effectivity and productiveness in comparison with their extra automated counterparts. Smaller labs, specifically, not must worry the up-front funding in automated excessive throughput liquid dealing with methods attributable to their reducing value, growing flexibility and smaller footprints of high-value, entry-level methods just like the ARI Scorpion. Investments in laboratory automation can reap vital rewards in knowledge high quality and total effectivity each now and sooner or later.