Briefly

Why it issues

- For producers: Understanding how friends see their future manufacturing unit and operations will help producers assess their very own transformation methods.

- For tech distributors: Staying apprised of how producers see their future factories will help distributors align their choices over the subsequent few years and stay aggressive.

Unprecedented investments in good factories

Spending on new factories at report highs within the US. US producers spent $193 billion on building in 2023, in line with the US Census Bureau. This spending represents a climb of 55% over 2022, when the US handed the Infrastructure Funding and Jobs, Inflation Discount, and CHIPS and Science Acts, all of which supposed to deal with inflation within the US and encourage the reshoring of key applied sciences, corresponding to semiconductors, built-in circuits, photo voltaic panels, and batteries. As of Could 2024, the seasonally adjusted annual charge for manufacturing building spending climbed to $233 billion, reflecting a continued drive for manufacturing enlargement by 2024.

Practically three-quarters of producers are remodeling present factories. Across the identical time these acts had been handed, Microsoft and Intel revealed IoT Indicators – Manufacturing Highlight, with the analysis performed by IoT Analytics. In line with the paper, 84% of producers had developed good manufacturing unit methods. These producers developed their methods in recognition that future operations and factories wanted to be extra versatile when confronted with uncertainty and shifting market dynamics, as skilled through the COVID-19 pandemic.

The query turns into, how are producers getting ready for the manufacturing unit of the long run? What are they working to implement to deal with turbulent market dynamics?

Current market insights reveal how factories are remodeling

Analysis into the factories of the long run offers insights into how producers are getting ready for the long run. In partnership with Microsoft, IoT Analytics performed a world survey of 500 producers in early 2024 to grasp the most recent tendencies, applied sciences, and priorities as they appear forward at the way forward for their operations, ensuing within the 52-page Speed up Industrial Transformation: How Producers Put together Store Flooring for a Future with AI report which is free to obtain on Microsoft’s web site. The report offers insights from the producers about how they envision their future operations, the challenges they face, and the way they’re getting ready now to deal with these challenges by investing into applied sciences corresponding to containerization, centralized gadget administration, and industrial information ops options.

Be aware: Microsoft revealed a weblog about the identical report in June 2024, titled: 6 findings:producers put together their store flooring for AI.

In the direction of the manufacturing unit of the long run: The highest 6 paradigms

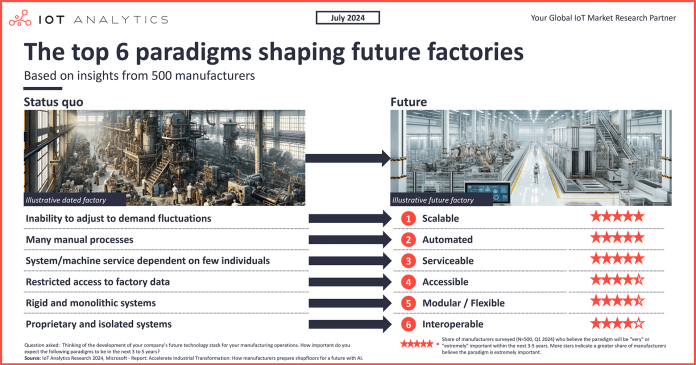

6 key paradigms stand out for producers. When requested to rank the significance of varied paradigms throughout the subsequent 3–5 years, the five hundred survey respondents, on common, indicated 6 paradigms as both very or extraordinarily essential. Briefly, factories needs to be 1) scalable, 2) automated, 3) serviceable, 4) accessible, 5) modular/versatile, and 6) interoperable.

1. Scalability

Scalability issues most. 72% of respondents indicated that scalability—the seamless capability to increase and scale down in response to market demand—is essential for his or her factories within the coming years. Scalable factories can replicate profitable processes throughout a number of websites, enhance effectivity, and cut back the necessity for important reinvestment when increasing operations. This helps in sustaining a aggressive edge in a dynamic market.

Voices from the business

“Essentially the most difficult side for us, in regard to the adoption of applied sciences, is the standardization between a number of vegetation, international locations, and areas.”

– Director of US-based automotive OEM overseeing optimization of producing operations throughout websites

2. Automation

Automation augments and even replaces guide processes. 70% of respondents rated automation—utilizing know-how to carry out duties that had been beforehand carried out manually—as both very or extraordinarily essential for his or her future factories. Automated factories can function with minimal human interplay, resulting in larger consistency and productiveness. Automation additionally allows real-time information monitoring and steady enchancment by superior analytics.

Voices from the business

“With automation on the store flooring, and particularly our MES system to streamline workflows throughout the worth stream, we will seize details about anomalies in equipment efficiency and mixture this to generate analytics for steady enchancment.”

– Senior manufacturing IT supervisor at a UK-based meals and beverage firm

3. Serviceability

Serviceability helps firms overcome expert labor gaps. 67% of respondents famous serviceability—the benefit with which manufacturing unit tools and methods may be maintained and repaired—as very or extraordinarily essential over the subsequent few years. Once they say they prioritize the serviceability of their property, they imply the reassurance that their machines will preserve working even throughout talent shortages.

As famous within the Speed up Industrial Transformation paper, the Germany-based equipment producer affiliation VDMA discovered that 80% of producing firms reported severe or noticeable bottlenecks as a result of talent shortages in 2022.

Voices from the business

“Know-how growth these days is so quick that my crew can’t all the time sustain.”

– Upkeep director of a South Korea-based engine producer

4. Accessibility

Accessibility helps the workforce benefit from technological advances. 62% of respondents marked accessibility as very or extraordinarily essential for his or her future factories. Accessibility means offering easy accessibility to manufacturing unit information and controls, usually by user-friendly interfaces and instruments. Making know-how accessible ensures that each one workers, no matter technical experience, can successfully use and profit from new methods. Accessible know-how helps construct a extra expert workforce, reduces coaching time, and enhances general productiveness, guaranteeing that essential information and controls are available for decision-making.

Voices from the business

“Making the know-how accessible to individuals by growing talent units is as essential because the know-how is for the OT setting.”

– Head of division at an India-based electrical energy era, transmission, and distribution firm

5. Modularity/Flexibility

Modular design and know-how parts guarantee producers stay versatile within the face of adjusting buyer preferences. Roughly 58% of respondents see modular and versatile manufacturing—processes and methods designed to be simply reconfigured and tailored to new merchandise or processes—as very or extraordinarily essential to their future operations. Flexibility permits producers to rapidly pivot to new alternatives or reply to adjustments in market demand with out important downtime or price, and modular methods allow sooner implementation of recent applied sciences and processes, lowering time to market.

Voices from the business

“Our highest precedence is to combine new software program capabilities in a modular style. We would like to have the ability to present real-time updates on stock and logistics to our prospects now. So, we have to add a bit of software program that’s modular sufficient so it doesn’t intrude an excessive amount of with the remainder of the system.”

-Vp at a US-based meals and drinks producer

6. Interoperability

Interoperable methods cut back general complexity. Lastly, roughly 58% of respondents indicated that interoperability—the power of various methods, units, and functions to work collectively seamlessly inside a manufacturing unit—was essential for his or her future factories. Interoperable methods allow extra environment friendly information sharing and integration, main to raised coordination and optimized operations. With it, producers can create a unified and coherent manufacturing setting, facilitating superior analytics, enhancing decision-making, and supporting the implementation of recent applied sciences like AI extra successfully.

Voices from the business

“After we undertake new know-how, our principal concern is concerning the integration and orchestration of various options. We have to face up totally different initiatives with totally different applied sciences in numerous areas, with totally different expertise and assets.”

-Chief X officer at a Germany-based laptop and digital merchandise manufacturing firm

How firms are getting ready for the manufacturing unit of the long run

Analysis for the Speed up Industrial Transformation report discovered that firms main the cost in realizing their factories of the long run, amongst different priorities, do three issues properly:

- They handle units effectively with centralized gadget administration. This includes managing industrial units, together with provisioning, certificates administration, well being and safety monitoring, and updating from a single, central location.

- They use containerized OT software program. Containerizing software program workloads permits new or up to date functions to include all the mandatory parts to run persistently on the edge or within the cloud, irrespective of the place they’re put in.

- They unify the information property with industrial information operations. This includes standardized information integration in a spot the place everybody can entry it. Industrial information ops are key applied sciences that handle and enhance information move, high quality, and worth inside an industrial context

Main adopters of future manufacturing unit applied sciences

Automotive OEMs are among the many most superior. In line with the report, the automotive business units the tempo for industrial digital transformation. 100% of respondents from automotive producers and suppliers reported that their organizations have containerized workloads, and 93% reported that their organizations are utilizing not less than one gadget administration answer.

Respondents shared that three automotive firms specifically are prime examples of remodeling their factories for the long run: BWM, Tesla, and Hyundai.

1. BMW

“BMW could be very a lot forward within the adoption of containerization. They’ve lowered their operational bills by approx. 50 %, I imagine, which could be very considerable, and digitally, they’ve achieved a really huge milestone.”

– Company IT director at a Singapore-based lifting and dealing with tools producer

2. Tesla

“Tesla has achieved large-scale battery manufacturing will increase, leveraging AI to assist detect points and high quality in manufacturing. They’ve achieved a really huge milestone.”

– Manufacturing director at a US-based producer of electronics and optical merchandise

3. Hyundai

“With the assistance of centralized gadget administration, [Hyundai was] capable of remotely monitor tools well being, vitality consumption, and efficiency of their manufacturing plant.”

– Senior manufacturing supervisor at a Japanese energy firm

Extra about how producers are getting ready for the manufacturing unit of the long run

Downloading the “Speed up Industrial Transformation” report

These 6 paradigms are solely a snapshot of the quite a few insights in Speed up Industrial Transformation: How Producers Put together Store Flooring for a Future with AI (free obtain by way of Microsoft). Together with studying the total report for extra details about these paradigms, producer challenges, and constructing blocks in realizing the manufacturing unit of the long run, IoT Analytics encourages readers to be taught extra about industrial digital transformation from latest analysis and reporting.

Extra IoT Analytics analysis on the subject

Associated market reviews

Upcoming market reviews

IoT Analytics plans to publish a number of associated reviews in Q3 and This autumn 2024:

- IoT Use Case Adoption Report 2024

- IT/OT Convergence Report 2024

- Industrial Software program Panorama 2024

- Industrial AI Market Report 2024 – 2030

Associated blogs

Associated market information

You might have an interest within the following IoT market information merchandise:

Are you interested by continued IoT protection and updates?

Subscribe to our publication and observe us on LinkedIn and Twitter to remain up-to-date on the most recent tendencies shaping the IoT markets. For full enterprise IoT protection with entry to all of IoT Analytics’ paid content material & reviews together with devoted analyst time try Enterprise subscription.